In the realm of materials science and general chemistry, the physical properties of substances play a crucial role in determining their applications and usability in various fields. One such physical property is malleability—the ability of a substance to be beaten into thin sheets without breaking. This article delves deep into the question: Which of the following can be beaten into thin sheets?

To fully understand this concept, we will explore the definition of malleability, the types of materials that exhibit this property, and a comprehensive comparison of various elements and compounds, with a specific focus on metals and non-metals. We will also review practical applications of malleable materials and how this property is tested and utilized in real-world scenarios.

Understanding Malleability

Malleability is a term used to describe a material’s ability to withstand deformation under compressive stress. It is one of the distinguishing features of metals and is closely related to another property called ductility, which refers to the ability to be stretched into wires.

Definition of Malleability

Malleability is defined as the ability of a material to be hammered, pressed, or rolled into thin sheets without breaking or cracking. It is a measure of how easily a substance can change shape under pressure.

Scientific Explanation

At the atomic level, malleability is due to the nature of metallic bonding. In metals, atoms are arranged in a lattice structure and share a “sea of electrons” that allows the atoms to slide over each other when force is applied. This prevents the metal from shattering and instead enables it to flatten or bend.

Examples of Malleable Materials

Now, let’s consider the actual question—which of the following can be beaten into thin sheets?—by examining common examples from various material categories.

1. Gold

- Most malleable metal.

- Can be beaten into sheets so thin that they are transparent.

- A single gram can be hammered into a sheet of about one square meter.

2. Silver

- Highly malleable and ductile.

- Widely used in jewelry and coinage.

- Less malleable than gold but still very capable of forming thin sheets.

3. Aluminum

- Light, soft, and malleable.

- Commonly used in foils and packaging materials.

4. Copper

- Excellent malleability.

- Used extensively in electronics, plumbing, and sheet metal work.

5. Platinum

- Durable and malleable.

- Often used in fine jewelry and catalytic converters.

These materials share the trait of being metals, which naturally tend to exhibit high malleability.

Metals vs. Non-Metals: A Comparison

When posed with a multiple-choice question such as, “Which of the following can be beaten into thin sheets: Iron, Sulphur, Phosphorus, Aluminum?”—the correct approach is to identify which options are metals and which are non-metals.

Properties of Metals

- Malleable

- Ductile

- Good conductors of heat and electricity

- Lustrous (shiny)

- High melting and boiling points

Properties of Non-Metals

- Brittle (when solid)

- Poor conductors

- Not malleable or ductile

- Dull in appearance

Conclusion: Only metals in a given list can be beaten into thin sheets.

Real-World Applications of Malleable Materials

Malleable materials play an essential role in various industries. Here are some notable applications:

1. Construction

- Copper and aluminum sheets are used in roofing, electrical wiring, and plumbing.

2. Packaging

- Aluminum foil is a ubiquitous packaging material due to its thinness and flexibility.

3. Electronics

- Gold, due to its excellent conductivity and malleability, is used in microchips and connectors.

4. Jewelry

- Gold, silver, and platinum are shaped into intricate designs thanks to their malleability.

5. Aerospace and Automotive

- Thin metal sheets are used for car bodies and airplane fuselages.

Laboratory Demonstration of Malleability

Malleability can be demonstrated through a simple hammer test in educational laboratories.

Materials Needed:

- Small pieces of metals (e.g., aluminum, iron, copper)

- Hammer

- Anvil or hard surface

Procedure:

- Place the metal piece on the hard surface.

- Gently strike it with a hammer.

- Observe whether it flattens into a thin sheet or breaks apart.

Observation:

- Malleable metals will flatten without cracking.

- Brittle materials will shatter or break.

Limitations of Malleability

While malleability is a desirable property, it also has limitations.

A. Temperature Dependency:

- Metals become more malleable at higher temperatures.

- Some metals may become brittle at low temperatures.

B. Alloying Effects:

- Pure metals are generally more malleable than alloys.

- For example, pure gold is softer than 18K gold, which is mixed with other metals for strength.

C. Work Hardening:

- Repeated hammering or rolling can lead to hardening of the metal, making it less malleable unless annealed (heat-treated).

FAQs on Malleability

Q1. Is iron malleable?

Yes, iron is malleable, especially when heated. However, it is not as malleable as metals like gold or aluminum.

Q2. Can non-metals ever be malleable?

Generally, no. Non-metals are brittle and break under pressure. Exceptions like graphite exist, but it still cannot be beaten into sheets.

Q3. What is the most malleable metal?

Gold is the most malleable metal known to man.

Q4. Are all metals malleable?

Most are, but some (like bismuth and antimony) are more brittle and less malleable.

Q5. How is malleability measured?

There is no standardized numerical scale, but it is evaluated based on the thickness to which a metal can be hammered without breaking.

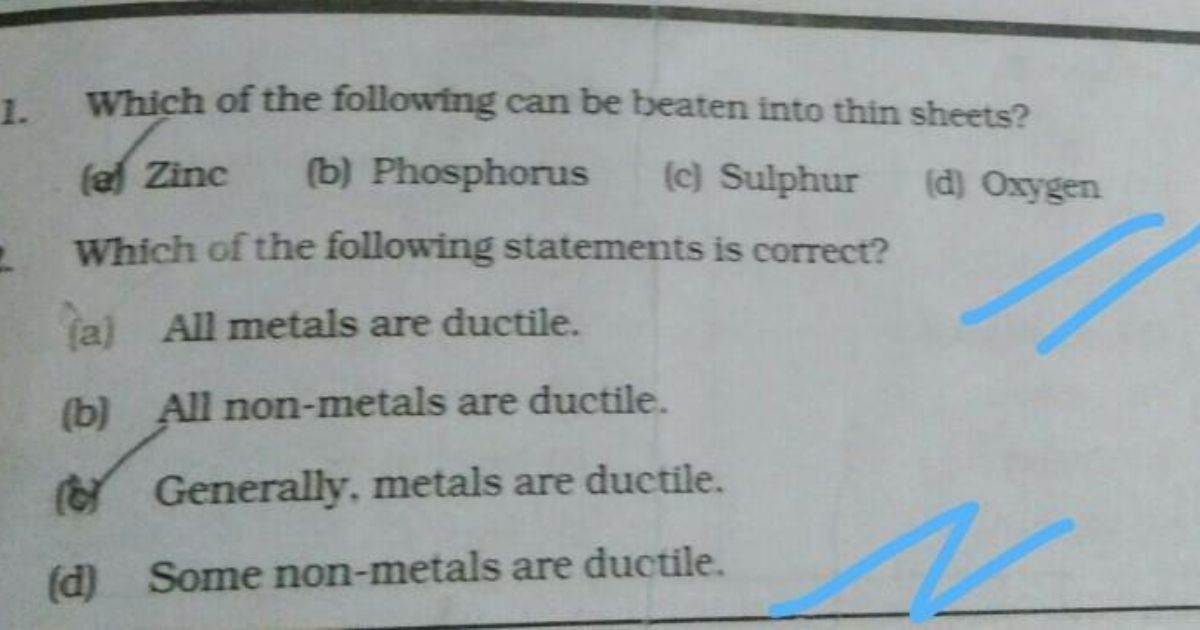

Educational Relevance: Textbook Questions

The phrase “Which of the following can be beaten into thin sheets?” is often found in science textbooks, especially in grades 6 to 9. It is commonly followed by options like:

- a) Sulphur

- b) Carbon

- c) Zinc

- d) Oxygen

Correct Answer: c) Zinc (as it is a metal)

This type of question tests students’ understanding of the physical properties of elements and helps them distinguish between metals and non-metals.

Summary Table: Malleability of Common Elements

| Element | Type | Malleable (Yes/No) | Notes |

|---|---|---|---|

| Gold | Metal | Yes | Most malleable element |

| Silver | Metal | Yes | Widely used in foils |

| Copper | Metal | Yes | Good electrical conductor |

| Aluminum | Metal | Yes | Lightweight and flexible |

| Iron | Metal | Yes (when heated) | Used in tools and construction |

| Sulphur | Non-metal | No | Brittle, used in chemical industry |

| Phosphorus | Non-metal | No | Highly reactive, brittle |

| Oxygen | Non-metal | No | Gas at room temperature |

Conclusion

The ability of a substance to be beaten into thin sheets is a defining trait of malleability, and this property is prominently exhibited by metals. So, when asked “Which of the following can be beaten into thin sheets?”, the correct approach is to identify the metals among the options.

Metals like gold, aluminum, copper, and silver are prime examples of malleable materials, used extensively in a wide array of industries ranging from electronics to aerospace. Understanding this fundamental property not only aids in academic learning but also forms the backbone of material selection in engineering and design.

So the next time you’re faced with this question, you’ll know the science behind it—and exactly which materials make the cut.